Meet our Member: thyssenkrupp rothe erde – Slewing bearings for wind energy plants

thyssenkrupp rothe erde has been researching and developing system solutions for various industries. The original company of thyssenkrupp rothe erde was founded in Dortmund in 1861. During its more than 160-year history, it was acquired by various groups before being integrated into thyssenkrupp AG in 1992.

thyssenkrupp rothe erde itself has over 11 companies with 14 plants in 10 countries and can offer customers innovative solutions for slewing bearings worldwide. One of the most important industries for thyssenkrupp rothe erde is the wind industry – although the company is manufacturing slewing bearings for a wide range of industries: construction, mining, the solar industry, transport, mechanical engineering, aerospace, medical appliances, and more.

Quality assurance through extensive R&D

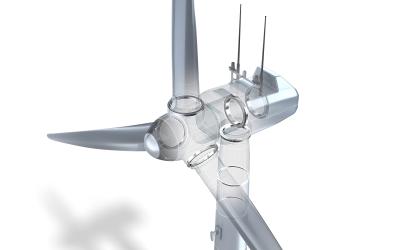

thyssenkrupp rothe erde manufactures all the slewing bearings and rings needed for a wind energy plant: the main bearings, yaw bearings, pitch bearings, gearbox bearings, and the flanges.

The worldwide presence and wide range of expertise are two of the strengths of the company. The third one is thyssenkrupp rothe erde’s extensive R&D with their testing facilities.

At the company’s beginning, the first test benches only took up a small space in manufacturing halls. This area grew to 1,200 square meters at the start of the 1970s, and in the spring of 2015, they began research operations in a newly founded and self-financed development center.

“With over 10,000 square meters it is the largest and most modern of its kind in the world,” says Peter Küpper, Vice President of Sales & Marketing at thyssenkrupp rothe erde. Additionally, all tests are being performed directly on the customer's original adjacent construction.

The test center is not only developing bearings and their components. It must also ensure a high level of quality by carrying out a continuous and recurring inspection, on a 1:1 scale, of the bearings and components from production. All this combined ensures that the product life of thyssenkrupp rothe erde solutions exceeds the application life cycle.

Product planning is the basis for success

The global wind turbine market is rapidly growing, which results in an increased demand for products, especially in the offshore area. To meet the requirements of this growing market, the development of reliable solutions manufactured within a sustainable series production is necessary.

thyssenkrupp rothe erde strongly believes that product planning is the basis for success. From the initial sketch up to implementation and servicing - with early involvement of customers and suppliers.

Following the best practice of the automotive industry, the APQP approach provides thyssenkrupp rothe erde with a very systematic, procedural, and standardized quality and production planning along the entire supply chain.

“The APQP4Wind concept is being requested more frequently in technical specifications and therefore developing gradually towards a standard,” says Peter Küpper and continues:

We have always put a lot of resources into our R&D and quality assurance, and we are always looking for ways to improve our approach to avoid tunnel vision. Therefore, it only felt natural to be trained in the APQP4Wind concept.

Since 2018, thyssenkrupp rothe erde has had 40 employees trained in the APQP4Wind concept, and in 2021, they became an APQP4Wind Company Member to take advantage of networking opportunities in the APQP4Wind community. Peter Küpper says:

“By being an APQP4Wind Company Member, we can take advantage of networking and exchanging ideas within the community, and we are bringing in our vast expertise when it comes to slewing bearings in the industry.”

Does your company also want to take the lead as an APQP4Wind Company Member and advance your business, career, and the industry like thyssenkrupp rothe erde?

Get involved and become a vital part of the development of APQP4Wind by signing up for a Company Membership. Find the form on the website under Become a Company Member or contact the Secretariat at contact@apqp4wind.org.

Core business: Development, manufacturing, and servicing of slewing bearings and rings for a wide range of industries, one of them being the wind industry since 1975.

Global presence: thyssenkrupp rothe erde itself consists of 11 companies with 14 plants in 10 countries. The headquarters are in Dortmund, Germany. The company is part of the thyssenkrupp group of companies.

Employees: 6,200 employees worldwide.

Website: www.thyssenkrupp-rotheerde.com

LinkedIn: thyssenkrupp rothe erde