Meet our Member: NGC – Geared for a better future

Global gearbox expert

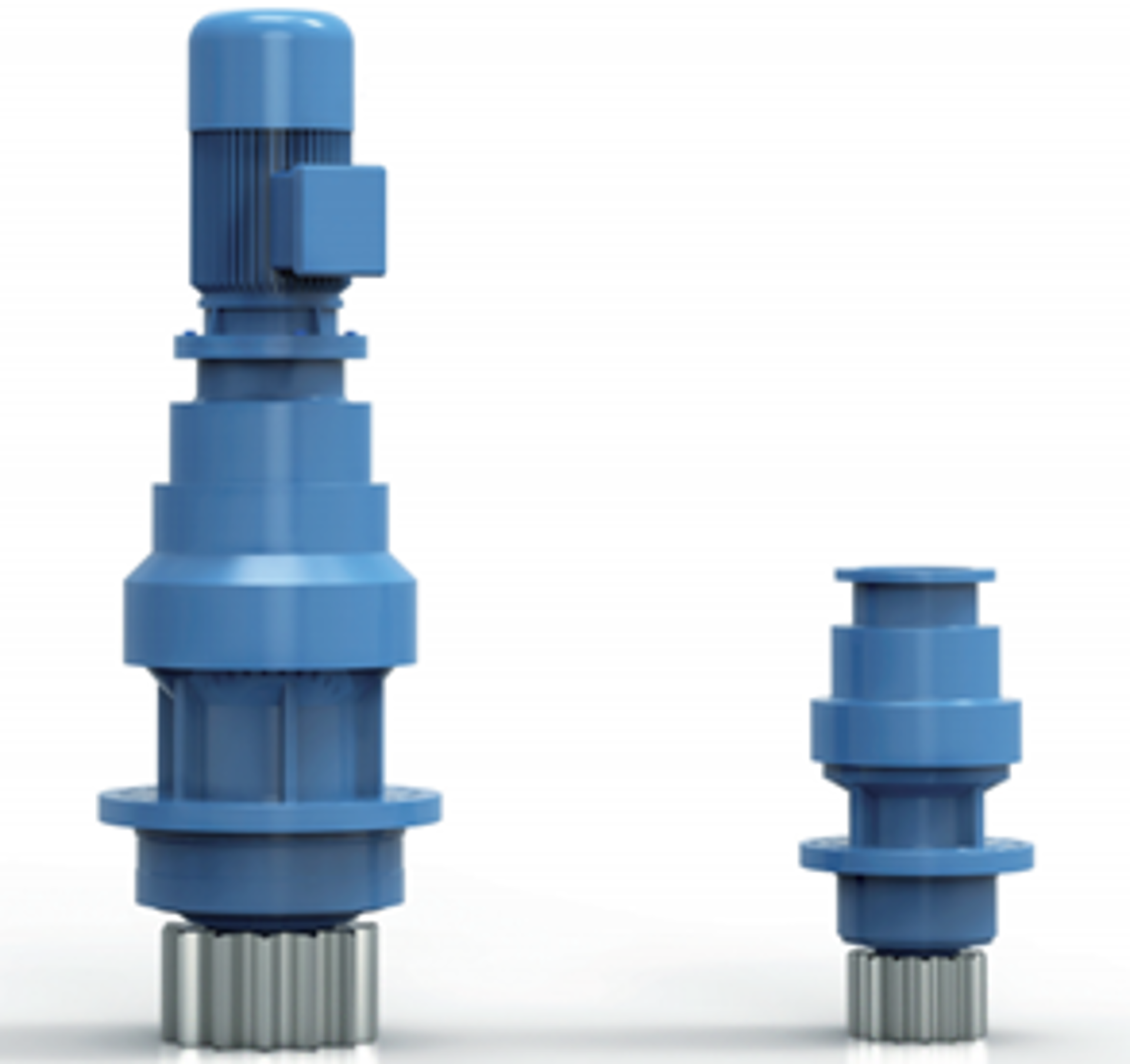

Since 1969, NGC has been a dedicated manufacturer of gearboxes and power transmission solutions for customers around the world. Their products are widely used in the wind power industry, but other industries also benefit from their solutions when developing industrial equipment, robot reducers, and new energy vehicle gearboxes. NGC's global market share of wind turbine gearbox products has continued to grow for many years by focusing on innovation and investing in the fields of clean energy, low consumption, and high efficiency.

Highly reliable wind turbine gearboxes

NGC maintains a long-term cooperative relationship with many domestic and foreign wind turbine manufacturers. Its products are distributed in more than 30 countries and regions. Based on a large database of wind farm applications, modularization, and serialization concepts, NGC launched StanGearTM, which is a series of product platforms of main gearboxes, yaws, and pitch drives designed to be effective under various harsh environments.

Focus on the global footprint to enhance the sustainable development

While consolidating the Chinese market, NGC has accelerated the strategic layout of its global operations and established operation and maintenance centers as well as service organizations in the Americas, Europe, and the Asia-Pacific region. These measures ensure that more customers around the world can enjoy high-quality products and services together with further enhancing NGC’s brand, their global service quality, and sustainable development worldwide.

Technological innovation leads the future

NGC has always been committed to technological innovation and progress. They focus on essential technology research of high-speed and heavy-duty gears, including ‘Key technology research and application of high-power wind turbine main shaft and gearbox bearing and construction of industrial verification platform’ and ‘Key technology of high-speed lightweight gear transmission system’ etc. Therefore, NGC participates in scientific and technological projects such as demonstration application of the digital platform of the gear transmission system for data analysis, as well as testing the high-efficiency lubrication and cooling technology of the GTF engine fan-driven gearbox.

Quality assurance frontrunner

Driven by the company's zero-defect management philosophy, NGC participated in an APQP4Wind Specialist Training Course in Beijing, China, in December 2017. Afterward, top management established an APQP4Wind project team to begin the internal preparations of the APQP4Wind implementation and integrate the various process documents and forms within NGC. By using APQP4Wind, NGC established a structured end-to-end product development system that connects customers and suppliers with NGC's internal processes and teams.

Quality Vice President of NGC, Mr. Zhen Liu says: “Initially, NGC’s quality assurance department was looking for ways to reduce risks and improve our internal processes. APQP4Wind proved to be the perfect solution for this as the standardized approach gives us a common language that ensures that we are aligned across our supply chain.”

Today, various functions within NGC have received a certification from having passed either an APQP4Wind Specialist or Management Awareness Training Course. This has made it possible to include APQP4Wind in processes within project management, design, sourcing, production, quality, etc., and create the foundation for the further application and promotion of APQP4Wind. The natural next step was to sign up for an APQP4Wind Company Membership as NGC would like to take advantage of the opportunities that come with being a part of the APQP4Wind Community, says Mr. Zhen Liu and elaborates:

“We chose to sign up for an APQP4Wind Company Membership to become a part of the APQP4Wind Community, where we can share ideas, learn from each other, and mature the wind power supply chain together with other industry experts. We see it as proof for our customers that we are quality assurance frontrunners.

APQP4Wind implementation to ensure customer satisfaction

Supported by top management, NGC actively promotes the implementation of APQP4Wind in major key projects, covering various new product development projects with European, American, and domestic customers. By implementing APQP4Wind in the product development system, the participation and support of customers and suppliers increased. This promoted the cooperation between internal project members and enabled all parties to focus on one goal: Ensuring the delivery and quality of the project and, in the end, improving customer satisfaction.

Mr. Zhen Liu says: “We have received very positive feedback from our customers after having implemented APQP4Wind as they benefit from a shorter product development cycle than before. The main difference is that we now have a clear framework that gives us the tools to identify gaps immediately and ultimately ensures a preventive approach to quality throughout the project.”

Maturing the supply chain

After having a great understanding of how to implement APQP4Wind, NGC works towards promoting and helping suppliers to introduce APQP4Wind within their organizations. This helps the suppliers to implement APQP4Wind on selected benchmark projects. By doing so, NGC achieves beneficial results while helping suppliers improve their internal processes and ultimately improving the maturity of the entire wind power supply chain.

Does your company also want to take the lead as an APQP4Wind Company Member and advance your business, career, and the industry like NGC?

Get involved and become a vital part of the development of APQP4Wind by signing up for a Company Membership. Find the form on the website under Become a Company Member or contact the Secretariat at contact@apqp4wind.org.

Core business: Engineering, manufacturing, and providing service of wind turbine gearboxes, industrial gearboxes, robot reducer business, and new energy vehicle gearboxes.

Global presence: Operations, maintenance centers, and service organizations in the Americas, Europe, and the Asia-Pacific region.

Employees: 6,000+

Website: www.ngctransmission.com