Meet our Member: Exel Composites – For forward thinkers

Global reach, local impact

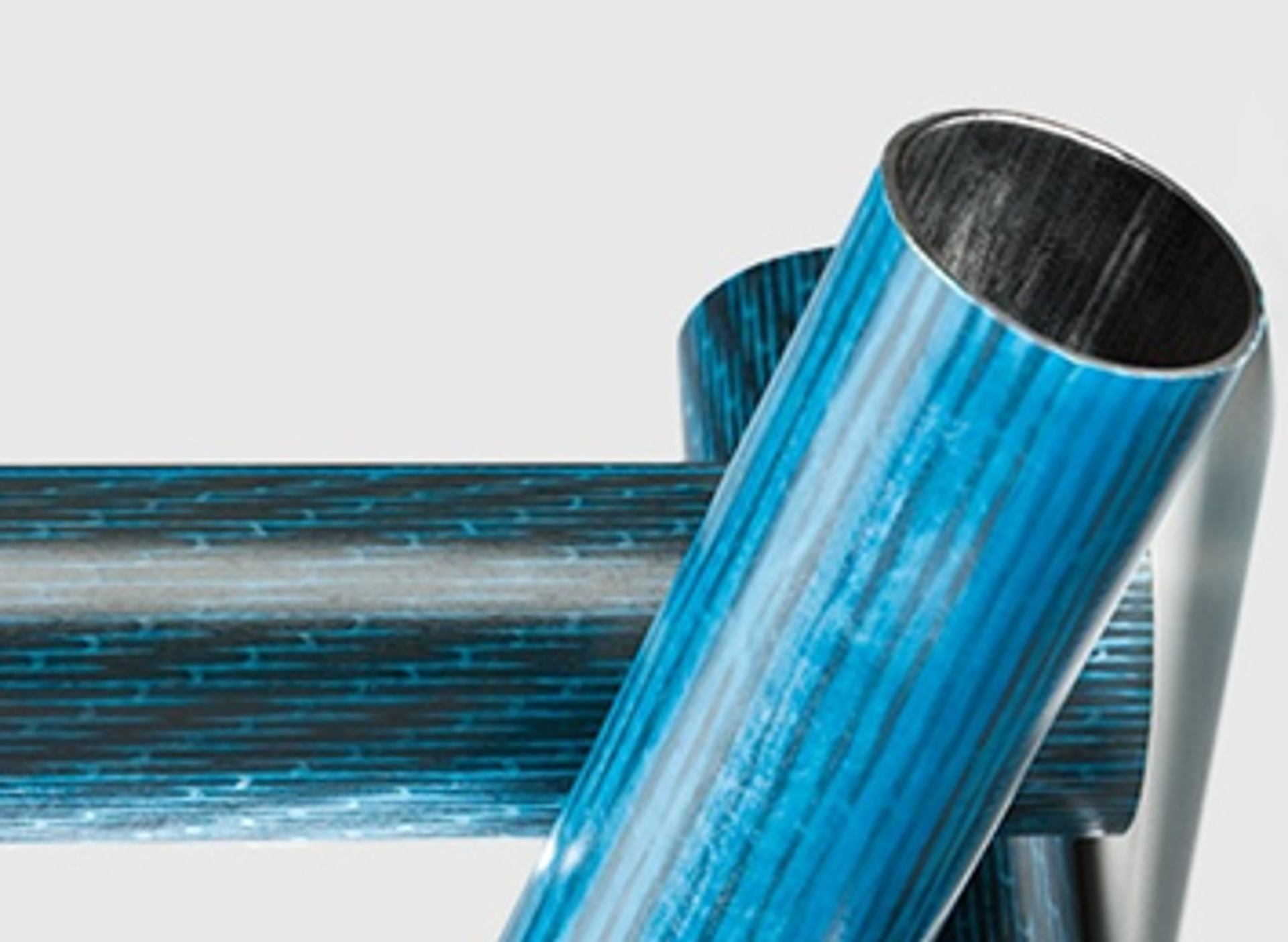

Headquartered in Finland and employing over 700 people worldwide, Exel Composites has produced composites for over 60 years. Today, the company produces composite materials for everything from trains and trucks to wind turbine blades, from window and door profiles to 5G mobile infrastructure.

R&D expertise, collaborative approach, and global footprint set the company apart from its competitors. Exel Composite aims to help customers save resources, reduce product weight, improve performance and energy efficiency, and decrease total lifetime costs.

Unique in its scope, Exel Composites is the only pultrusion company with a manufacturing presence in all major markets, including Europe, Asia, and North America. This global footprint allows Exel to compete effectively worldwide, offering solutions that meet diverse customer needs across geographies.

In the rapidly growing wind sector, Exel Composites has carved a niche by producing an extensive range of fiberglass and carbon fiber composites. These include spar cap flats, spacers, and pin-joint profiles, which are essential for modern wind turbines. Under the leadership of the new CEO, Paul Sohlberg, who took the helm in March 2023, Exel is set to enhance its presence in the wind market significantly.

Commitment to quality

Identifying APQP4Wind methodology as a key means of growth in the wind industry, Exel Composites started its APQP4Wind journey in 2021. The company initially certified a global team formed by Sales, Management, and R&D specialists who achieved Management Awareness and Specialist Training to support the global implementation within the company. First APQP4Wind membership was achieved with the company´s joint venture in India in October 2022, now it is extended to facilities in China and the US. Eventually, it will roll out to other facilities across the world.

“Joining APQP4Wind is a strategic step for us as we aim to align our operations with the best quality standards in the industry. This membership is not just about adhering to norms but pushing the envelope on what composite materials can achieve in wind technology.

Patricia explains the reason further: “Although Exel Composites is certified by ISO 9001, we want to implement a quality guideline that is specifically designed for the wind industry. We aim to develop a robust quality assurance methodology across wind production plants and lines, strengthen collaboration with wind customers by speaking a common language, and reduce the cost of poor quality.”

Advancing towards a sustainable future

Looking ahead, Exel Composites is poised to further influence the global wind energy market. It plans to extend the application of APQP4Wind standards across all its operations worldwide. This global strategy underscores Exel's commitment to sustainable energy solutions and its role as a key player in the renewable energy transition.

Exel Composites' participation in APQP4Wind underscores its dedication to quality and efficiency, with a focus on continuous improvement in all facets of its operations. It has integrated the ISO Quality Standard with the APQP4Wind methodology to ensure all requirements are met, from the Planning and Definition stage until the Production Part Approval Process is completed and serial production starts.

With the new APQP4Wind quality guidelines, Exel Composites will continue to expand its offering in the wind market. It can produce many other turbine-related composites using the pultrusion and pull-winding processes, including ladder profiles, cable management systems, crane beams, insulating parts, and more.

Does your company also want to take the lead as an APQP4Wind Company Member and advance your business, career, and industry like Exel Composites?

Get involved and become a vital part of the development of APQP4Wind by signing up for a Company Membership. Find the form on the website under Become a Company Member or contact the Secretariat at contact@apqp4wind.org.

Core business: Composites for wind turbine applications, using pultrusion, pull-winding, and continuous lamination processes

Global presence: Headquarters in Finland, major markets in Europe, Asia, and North America.

Employees: 700+

Website: Exel Composites

Linkedin: Exel Composites