Meet our Member: Cooper Turner Beck – Safety-critical fasteners

Unrivalled safety-critical fasteners

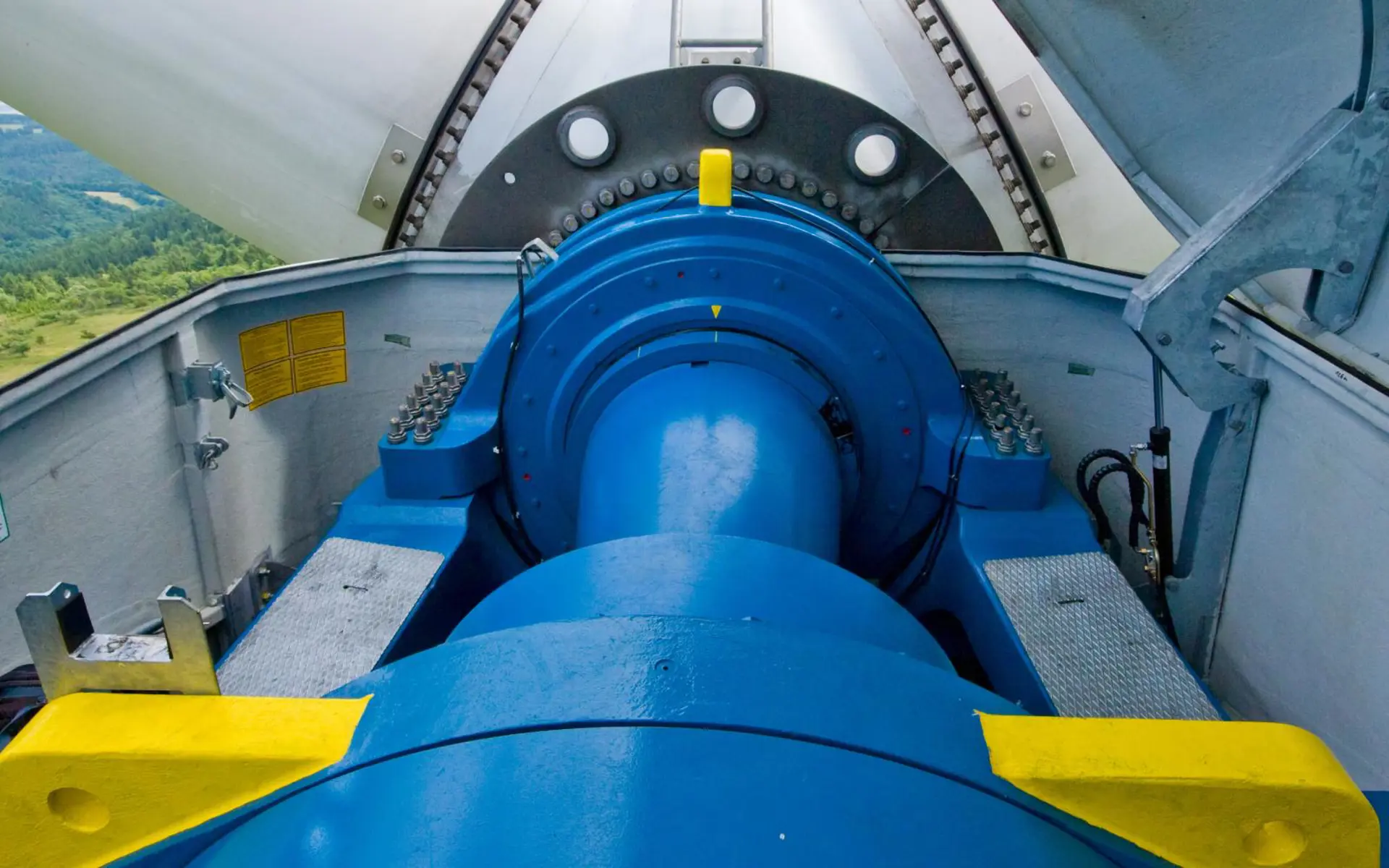

Cooper Turner Beck specializes in manufacturing and distribution of safety-critical fasteners for wind turbines and is especially known for their fasteners’ high strength and quality.

Cooper Turner Beck's fasteners are utilized by OEM's across the entire turbine, starting at the foundations with anchor cage hardware, moving up the tower with flange bolting, then with a range of fasteners throughout the nacelle, before finally securing the blades with high-strength studs.

With more than 25 years of experience within the wind turbine market and 10 production and distribution sites across Europe, North America, and Asia that hold more than 1,000 employees, Cooper Turner Beck is an unrivalled global leader of safety-critical fasteners.

Increased quality and reliability

In the beginning, Cooper Turner Beck had 5 of their core employees from the UK and China undergo APQP4Wind Specialist and Management Awareness Training conducted by approved APQP4Wind Training Providers. Now, employees across the various levels of the company are trained in APQP4Wind.

With the implementation of APQP4Wind, the company aims to increase product reliability for the end-customer and remove the costs associated with poor quality, Head of Global Quality and Technical Information at Cooper Turner Beck, Dave Briggs says:

“APQP4Wind is helping Cooper Turner Beck show current and potential customers our willingness not only to sustain our high quality standards, but also to improve our manufacturing process to further increase the quality and consistency of the products we manufacture.

APQP4Wind helps see areas for improvement

Along with helping Cooper Turner Beck improve product reliability, implementing APQP4Wind also helped the company realize the areas in their production that could be improved to create a more seamless cooperation with their customers, Quality Assurance Manager at Cooper Turner Beck, Neil Pearson says:

“Following the APQP4Wind concept has allowed us to see areas of our production that could be improved to help give more consistent products to our customers. The APQP4Wind concept helps us provide increased information to our customers in a specific format that decreases the timeframe of new qualification.

As a company driven by manufacturing and supplying high-quality products, the vast benefits of adopting the APQP4Wind concept motivated Cooper Turner Beck to become a part of the APQP4Wind Community.

Committed Company Member

Not long after implementing APQP4Wind, Cooper Turner Beck chose to become a Company Member to show their commitment to APQP4Wind and support the development of good practice within the wind industry.

Cooper Turner Beck’s APQP4Wind Company Membership maintains their position as a market leader within the manufacture of safety-critical fasteners, helps the company embrace the quality standardization for the wind industry, and enables the turbine OEM’s to have confidence in the supplied products. Head of Global Quality and Technical Information at Cooper Turner Beck, Dave Briggs expresses:

“The introduction of APQP4Wind within the market is already helping drive our customers to become more harmonic and look at creating harmonized standards, and Cooper Turner Beck is already in discussion with a number of large OEM’s in developing these standards.

Being a committed APQP4Wind Company Member, Cooper Turner Beck also had their Quality Assurance Manager, Neil Pearson, become an APQP4Wind Country Ambassador in the UK. As a Country Ambassador, he helps strengthen the familiarity and knowledge of the APQP4Wind concept in the UK and guides people with technical expertise and practical information.

Does your company also want to take the lead as an APQP4Wind Company Member and advance your business, career, and the industry like Cooper Turner Beck?

Get involved and become a vital part of the development of APQP4Wind by signing up for a Company Membership. Find the form under 'Why Become a Member?' on www.apqp4wind.org or contact the Secretariat.

Core business: Manufacturing and supplying safety critical fasteners for wind turbine towers

Global presence: 10 production and distribution sites around the world

Employees: 1,000+

Website: www.cooperandturner.co.uk

LinkedIn: The Cooper & Turner Group